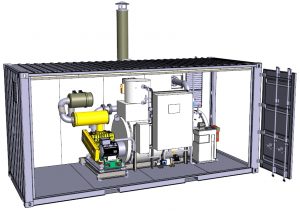

Steam-Jet is a heating system for concrete factories and are available in two models STEAM-JET 500 & STEAM-JET 2000. The two models are built with the same hot air aggregate/silo heating unit, but the STEAM-JET 2000 has in addition to this, also a high capacity hot-water heating system, able to supply hot water for: concrete mixers, heating of factory/office, warm water to truck or other needed areas. The two systems are 100% independently operating. The automated system allows just the amount of energy produced, that the production requires thus enabling remarkable savings.

This is how it works:

From the air heater a large amount of low pressure air is provided from the compressor. As the air passes through the heating aggregate, the temperature rises to the wanted pre-set temperature. At the same time water is pumped through the heating aggregate and economizer, utilizing the last energy in the flue gases. at this point the water has turned into low pressure steam. This steam is then added into the hot air, preventing the aggregate from drying out during heating. this method increases the effect remarkable and resulting in remarkable energy savings. STEAM-JET is in-direct heated, eliminating any risk due to exhaust gases.

Steam-Jet can be fired by natural gas, oil or propane.

The system can be operated either locally on touch panel or it can be operated remotely in your control room.

If you want to hear more about our hot air system or if you want to hear what solution we can help you with, feel free to contact us.

Technical information

| 1. | Hot Air | ||

| amount of air | 2200 – 2800 | m3 / h | |

| 0,6 – 0,8 | m/s | ||

| air temperature | 220 – 260 | C | |

| water amount | 80 – 150 | l/h | |

| 2. | Heat exchanger | ||

| Thermal performance | 200 – 500 | KW | |

| efficiency | 94 – 97 | % | |

| material | HST | 1,6 MPa | |

| 3. | Economizer | ||

| Heat recovery | |||

| 4. | Flue gasses | ||

| temperature | 150 – 190 | C | |

| 5. | Compressor | ||

| air flow | 2200 – 2800 | m3 / h | |

| 0,6 – 0,8 | m/s | ||

| working pressure | 0,4 | Bar | |

| 6. | Burner | ||

| Oil | |||

| Gas | |||

| 7. | Water treatment | ||

| water supply pressure | 4 – 6 | Bar | |

| automatic regeneration | |||

| 8. | Other information | ||

| control | Local / Remote | ||

| dimenaions | 6500 X 2440 X 2590 | ||

| weight | ~6000 kg | ||

| electrical requirements | 400 VAC, 50Hz, 100A |